MGT300 - CHAPTER 10

Extending the organization – Supply Chain Management (SCM)

- The

average company spends nearly half or every dollar that it earns on

production

- In

the past, companies focused primarily on manufacturing and quality

improvements to influences their supply chains

- The

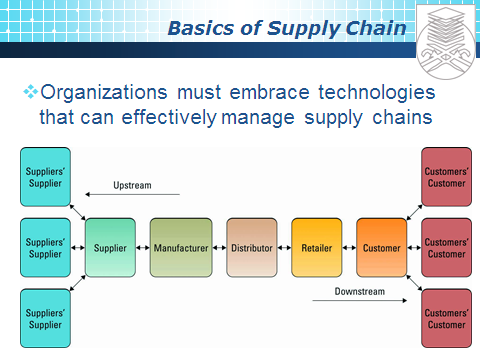

supply chain has three main links :

Ø Materials flow from suppliers and their 'upstream' suppliers at all

levels

Ø Transformation of materials into semifinished and finished products

through the organization's own production process

Ø Distribution of products to customers and their 'downstream' customers

at all levels

Ø Plan

A company must have a plan for

managing all the resources that go toward meeting customer demand for products

and services

Ø Source

Companies must carefully choose reliable

suppliers that will deliver goods and services required for making products

Ø Make

This is the step where companies

manufacture their products or services. This can include scheduling the

activities necessary for production, testing, packaging and preparing for

delivery

Ø Deliver (logistic)

Companies must be able to receive

orders from customers, fulfil their orders via a network of warehouses, pick

transportation companies to deliver the products and implement a billing and

invoicing system to facilitate payments

Ø Return

This is typically the most

problematic step in the supply chain. Companies must create a network for

receiving defective and excess products and support customers who have problems

with delivered products

Ø Visibility

More visible models of different ways to do things

in the supply chain have emerged. High visibility in the supply chain is

changing industries, as Wal-Mart demonstrated

Ø Supply chain visibility

The ability to view all areas up and down the

supply chain

Ø Bullwhip effect

Occurs when distorted product demand information

passes from one entity to the next

throughout the supply chain

Ø Supply chain visibility allows organizations to

eliminate the bullwhip effect

*To explain the bullwhip effect

to your student discuss a product that demand does not change, such as diapers.

The need for diapers is constant, it does not increase in Christmas or in the

summer, diaper are in demand all year long. The number of newborn babies

determines diaper demands, and that number is constant.

*Retailers order diapers from

distributors when their inventory level falls below a certain level, they might

order a few extra just to be safe

*Distributors order diapers from

manufactures when their inventory level falls below a certain level, they might

order a few extra just to be safe

*Manufacturers orders diapers

from suppliers when their inventory levels below a certain level, they might

order a few extra just to be safe

*Eventually the one or two extra

boxes are ordered from a few retailers becomes several thousand boxes for the

manufacturer. This is the bullwhip effect, a small ripple at one end makes a

large waves at the other end of the whip

Ø Consumer behaviour

*Companies can respond faster and

more effectively to consumer demands through supply chain enhances

*Once an organization understands

customers demand and its effect on the supply chain it can begin to estimate

the impact that its supply chain will have on its customers and ultimately the

organization performance

*Demand planning software –

generates demand forecast using statistical tools and forecasting techniques

Ø Competition

*Supply chain planning

software(SCP) – uses advanced mathematical algorithm to improve the flow and

efficiency of the supply chain

*Supply chain execution software

(SCE) – automates the different step and stages of the supply chain

*SCP and SCE both increase a

company‘s ability to compete

*SCP depends entirely on

information for its accuracy

*SCE can be as simple as

electronically routing orders from a manufacturer to a supplier

Ø Supply chain management success factors

*Make the sales to suppliers

*Wean employees off traditional

business practices

*Ensure the SCM system supports

the organizational goals

*Deploy the incremental phases

and measure and communicate success

Ø DSSs allows managers to examine performance and relationship over the supply chain and among:

*suppliers

*manufacturers

*distributors

Comments

Post a Comment